载氢金属辉光放电实验报告 张航最新进展

2018-02-05 12:19:58 来源:冷聚变世界 评论:0 点击:

本实验是西安秋然实验室的张航工程师参照日本氢能工程应用开发公司水野忠彦教授的实验,对装置改进设计,进行了载氢金属辉光放电实验。他在实验中发现了一些异常的放热现象。

本实验参照日本氢能工程应用开发公司水野忠彦教授的实验,对装置改进设计,进行了载氢金属辉光放电实验,观察到了一些现象,现将实验总结如下。

According to the experiment of Professor Mizuno Tadahiko of Hydrogen Engineering Application & Development Company, we carried out the experiment of hydrogen carrying metal glow discharge and observed some phenomena. The results are summarized as follows.

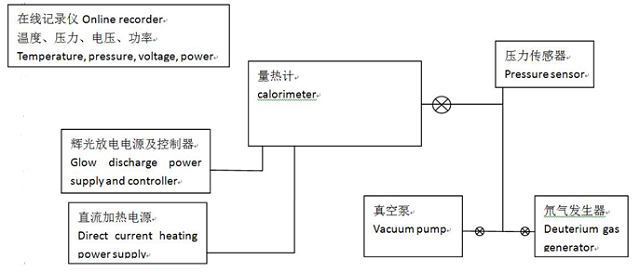

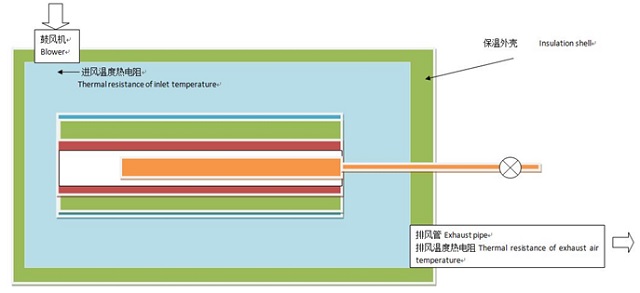

总体实验系统如下

The overall experimental system is as follows

The overall experimental system is as follows

实验系统图

Experimental system diagram

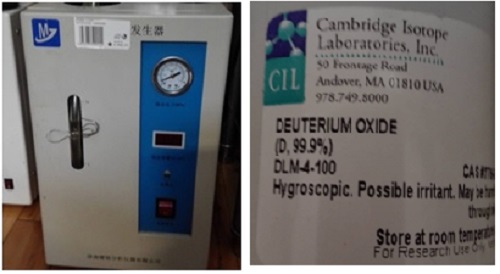

氘气发生器和重水

Deuterium gas generator and heavy water

真空泵 加热直流电源 功率表

Vacuum pump Heating DC power supply Power meter

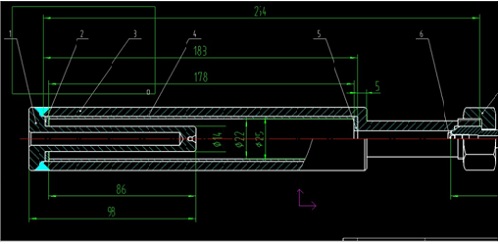

反应容器 照片

Reaction vessel Photo

反应容器剖面图

Reaction vessel profile

容器用不锈钢制作,内衬镍皮,容器右侧的套管是测温套管,测温套管包裹镍皮,内插一根热电偶,热电偶瓷管绝缘,容器左侧插入一根瓷管,瓷管内插入镍电极,镍电极由直径0.5镍丝制作,放电部位做成螺线管形状。见下图,容器内装入2克镍粉和0.2克氢化铝锂Reaction vessel profile

A container was made of stainless steel with nickel leather lining. The right side of the container casing was the temperature measuring sleeve, nickel skin, tube insulation container with a thermocoulple in it. The left side of the container was a porcelain tube with a nickel electrode in diameter of 0.5 mm, the discharge part was in solenoid shape. The container was loaded with 2 grams of nickel powder and 0.2 grams of aluminum lithium hydride.

镍电极

Nickel electrode

In these experiments, the forward discharge and reverse discharge ere carried out. The electrode is positive when the forward discharge is positive, and the electrode is negative in reverse discharge.

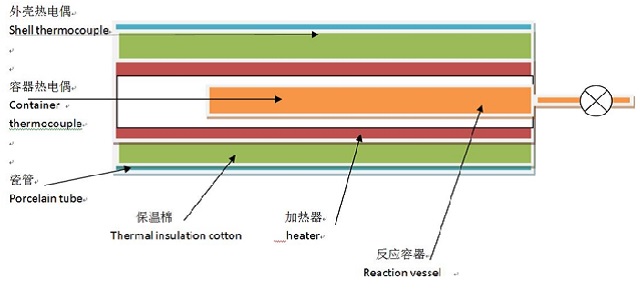

反应装置剖面图

Reaction unit profile

Reaction unit profile

容器放入加热器中,加热器外包保温棉,保温棉外做瓷管护壳,容器测温点插入一只热电偶,外壳内侧插入1只热电偶。

The container was put into a furnace Its heater was insulated by the thermal insulation cotton with outside porcelain tube as guard shell. The temperature measuring point of the furnace is inserted into a thermocouple, and another thermocouple is used in the inner side of the shell.

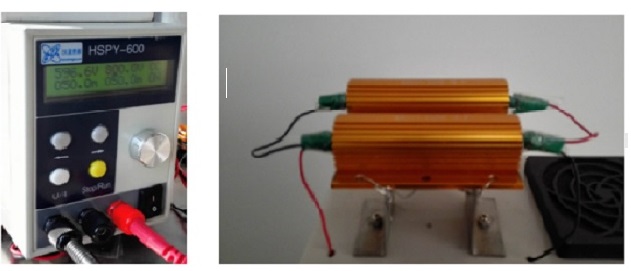

辉光放电电源和限流电阻

Glow discharge power supply and The current limiting resistor

Glow discharge power supply and The current limiting resistor

辉光放电电源是直流稳压稳流电源,可进行稳压控制也可以稳流控制,输出电压0-1000伏,输出电流0-100毫安

The power supply is DC stabilized power, voltage control can also be steady flow control, the output voltage is 0-1000 V, the output current is 0-100 mA

限流电阻阻值5k欧姆,功率100瓦,两个并联,总电阻2.5k欧姆,串联在放电回路中

Two resistance (5 k-ohms, 100 watts) were parallel to a total resistance of 2.5 k-ohm, it was used in discharge circuit for series connection.

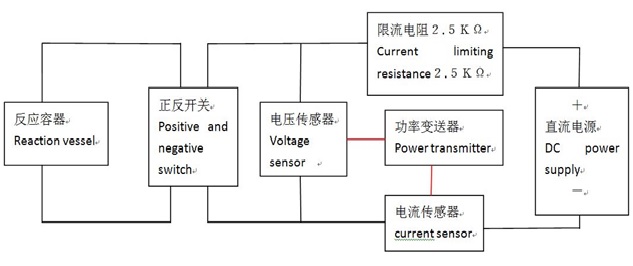

辉光放电电路

Glow discharge circuit

The discharge circuit is shown in the diagram; the voltage sensor and the current sensor are installed in the controller.

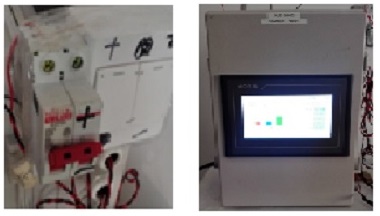

正反向开关和辉光放电控制器

Forward and reverse switch and Glow discharge controller

Forward and reverse switch and Glow discharge controller

正反向开关实验时(见上图右),正向位置时容器外壳为负极,容器内电极为正极,对燃料进行预处理时可进行正反向轮换。

In experiments, the positive position of switch corresponded the negative electrode of the container and the positive polarity of inner electrode in the container. The polarity could be reversed when the fuel is pretreated.

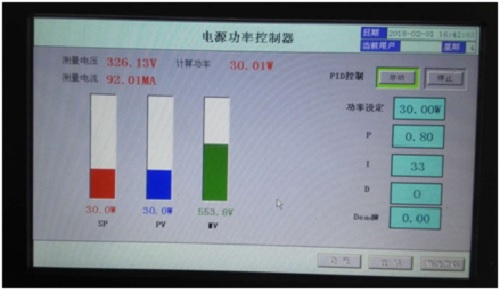

辉光放电控制器人机界面

The Human Machine Interaction of the glow discharge controller(LEFT)

这个控制器内部安装电压传感器和电流传感器,用西门子s7-200型PLC作为控制器,计算出功率,控制电源的输出电压,保持辉光放电的恒定功率,并向在线记录仪输出放电电压、放电功率信号,由这两个信号可以计算出,放电电流和放电电阻。

The controller had a voltage sensor and a current sensor with a controller of SIEMENS S7-200 PLC. The output power was calculated and the voltage was controlled. Power supply of glow discharge was controlled to be constant. The output discharge voltage, discharge power signal were in-situ recorded. The discharge current and discharge resistance were calculated by these two parameters.

量热计

The amount of heat exchanger

The amount of heat exchanger

量热计是通风式量热计(见上图),保温外壳内安放反应装置,向量热计内送入空气,空气送入量恒定,计量送风和排风的温差,计算出发热量。

The calorimeter is a ventilated calorimeter. The reaction device is placed inside the insulation shell, the air is sent into the air inside the calorimeter, the air input volume is constant, the temperature difference between the air supply and the exhaust is measured, and the thermal power is calculated.

在线记录仪

Online recorder

Online recorder

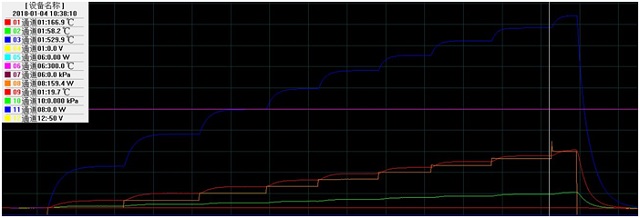

在线记录仪 通道介绍,

Online recorder channel introduction:

1外壳热电偶 Shell thermocouple

2排风温度 Exhaust air temperature

3容器温度 Container temperature

4辉光电压 glow voltage(V)

5辉光功率 Glow power(W)

6备用通道 Standby channel

7容器压力 Vessel pressure(kpa)

8加热功率 heating power(W)

9送风温度 air supply temperature (℃)

10备用通道 Standby channel

11备用通道 Standby channel

12放电正反向标识 Positive and reverse marking of discharge

空白实验

Blank experiment

空白实验用于标定加热功率与进排风温差的对应关系。

The blank experiment was used to calibrate the corresponding relationship between the thermal power and the exhaust air temperature difference.

组装好实验装置。

Assemble the experimental device.

放入空白容器

Put in a blank container

加热器通电,输入20、40、60、80、100、120、140、160瓦功率

The heater was power on and input power was 20, 40, 60, 80, 100, 120, 140, 160 watts, respectivley.

每个功率恒定维持8小时以上

Each power was maintained at a constant level for more than 8 hours

记录平衡时各项参数

Steady parameters were recorded

计算送排风温差与输入功率的对应关系

The calculation of the relationship between the air temperature difference and the input power

推导出经验公式

Derivation of empirical formula

空白实验记录仪显示画面

Blank experiment recorder display screen

空白实验统计表(下面)

Blank test statistics table(below)

Blank test statistics table(below)

| 容器外壳 温度 Container shell temp(℃) |

排风 温度 Exhaust air temp(℃) |

容器 温度 Container temp (℃) |

加热 功率 heating power (W) |

送风 温度 air supply temp (℃) |

进排风温差 Inlet and exhaust air temp difference |

计算功率 Calcul -ated power (W) |

偏离 devia- tion |

| 20.4 | 20.3 | 20.2 | 0 | 20.3 | 0 | -0.34 | -0.34 |

| 40.3 | 24.6 | 137.8 | 20 | 19.9 | 4.7 | 20.78 | 0.78 |

| 60.5 | 29.3 | 229 | 40.5 | 19.9 | 9.4 | 41.48 | 0.98 |

| 79.8 | 33.9 | 298.8 | 60.9 | 20 | 13.9 | 60.90 | 0.01 |

| 98.2 | 38.6 | 357.5 | 80.8 | 20.2 | 18.4 | 79.94 | -0.85 |

| 116.9 | 43.6 | 409.3 | 101.2 | 20.3 | 23.3 | 100.23 | -0.97 |

| 133.9 | 48.3 | 452.7 | 120.2 | 20.3 | 28 | 119.25 | -0.94 |

| 150.7 | 53.2 | 493.2 | 139.7 | 20.1 | 33.1 | 139.41 | -0.28 |

| 166.9 | 58.1 | 529.9 | 159.4 | 19.7 | 38.4 | 159.84 | 0.43 |

上表中计算功率为经验公式 ,w= x*4.54-x*x*0.0096-0.343,w—计算功率,x—进排风温差

The calculation power in the above table is an empirical formula, w= x*4.54-x*x*0.0096-0.343, W - calculating power, X - inlet and exhaust temperature difference

测量精度不高,误差±1 W

The accuracy of measurement is not so high and the error is ±1 W

The calculation power in the above table is an empirical formula, w= x*4.54-x*x*0.0096-0.343, W - calculating power, X - inlet and exhaust temperature difference

测量精度不高,误差±1 W

The accuracy of measurement is not so high and the error is ±1 W

实验经过

Experimental Process

1、 容器内放入2克镍粉,0.2克氢化铝锂,常温下抽真空,加热至200度,维持24小时后排出氢气,抽真空

1, 2 grams of nickel powder and 0.2 grams of aluminum lithium hydride were put in the container. The vessel was extracted at normal temperature, then heated to 200 degrees for 24 hours, then evacuated again to extract hydrogen.

2、 正式实验从2018年1月11日10.26开始,2018年1月23日19.00结束,容器内充入氘气,进行辉光放电和加热,观察不同状态下数据变化

2, The experiment was started from 10:26 January 11, 2018, and ended in 19:00 January 23, 2018. The deuterium gas was filled into the container, and glow discharge and heating were carried out to observe the data changes under different conditions.

3、 量热计测量的发热功率减去输入功率为超热,因为量热计热惰性较大,改变工况后6小时达到平衡状态,只能在平衡状态下观察超热,非平衡状态下不能观察是否产生超热。

3, The thermal power measured by the calorimeter was less than the input power. Because the thermal inertia of the calorimeter was large, and the equilibrium state was reached 6 hours after changing the working condition. The excess heat was observed only in the equilibrium state. We cannot observe whether the excess heat occurs in the non-equilibrium state.

观察到的现象

Observed phenomena

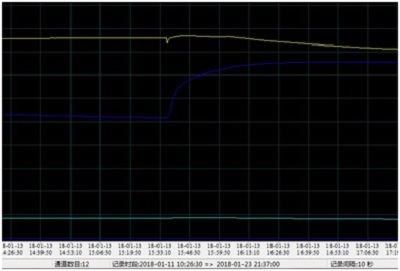

1、 异常温升

1. Abnormal temperature rise

图中上部黄色线条为辉光放电电压,中间蓝色线条为容器温度。下部浅蓝色线条为辉光放电功率。

The yellow line in the upper part of the graph was glow discharge voltage, and the blue line in the middle was the temperature of the container. The lower light blue line in the lower part was glow discharge power.

2018年1月13日15时30分,在辉光放电功率基本恒定条件下,容器温度从258度升高至377度,温升100度以上,不过在量热计中未能计量出超热。

A temperature rise of 100 degrees from 258 degrees to 377 degrees was observed after 15:30 January 13, 2018, in the glow discharge power under the condition of constant temperature container. However, no excess heat was shown in the calorimetric measurement.

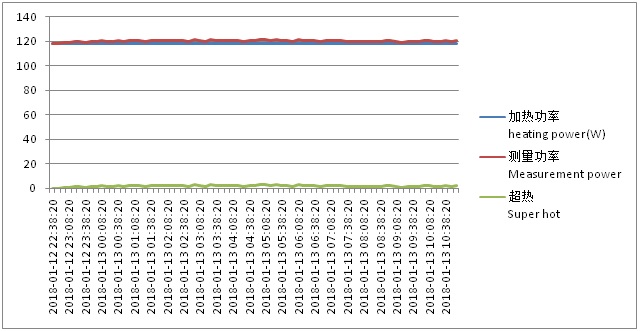

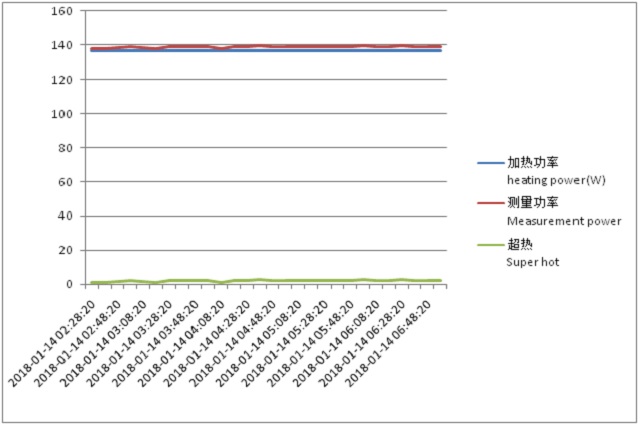

2、加热状态下的超热

2, the excess heat under the condition of heating

2018年1月12日23.00-2018年1月13日10.00,在118瓦恒定功率加热时出现超热,平均超热2.07瓦,如果减去误差1瓦,平均超热功率1.07瓦[l1] ,cop=1.01,产生热量42 kJ。

In 23:00 January 12, 2018 to10:00 January 13, 2018. when 118 watts of constant power was applied, it appeared excess heat, and the average excess power was 2.07 watts. If the error is 1 watts, the average super heat power is 1.07 watts, cop=1.01 will generate heat 42KJ.

[l1]误差只是说明不确定度,不应该减去。

In 3:00 to 7:00 January 14, 2018, when 137 watts constant power heating was applied, average excess power of 1.8 watts was observed. if the error is 1 watts, the average super heat power is 0.8 watts, cop=1.005, generate heat 11KJ[l1] .

[l1]问题同上

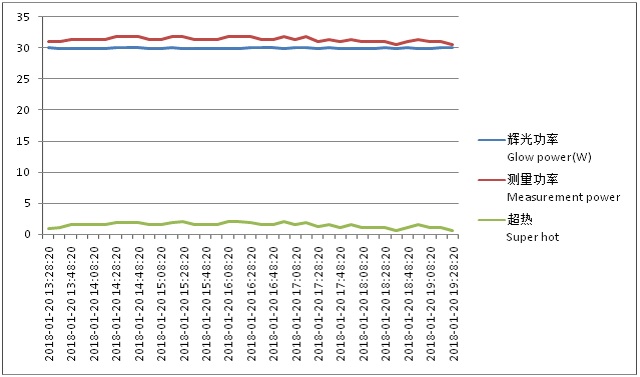

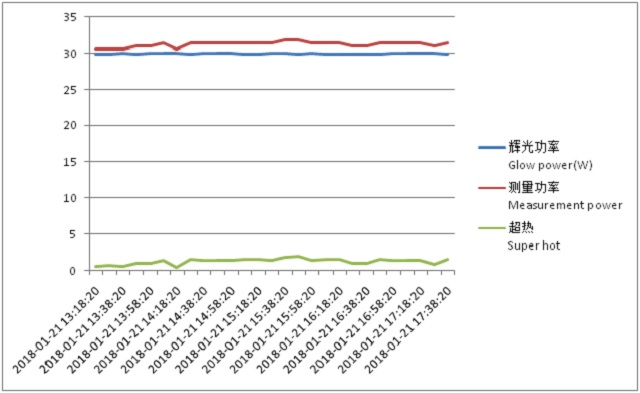

3、辉光放电时的超热

3, the excess heat of the glow discharge

2018年1月20日14.00- 18.00,在30瓦恒定功率辉光放电时出现超热,平均超热1.6瓦,如果减去误差1瓦,平均超热功率0.6瓦,cop=1.02,产生热量8.6KJ。

In 14:00 to 18:00 January 20, 2018, when 30 watts constant power of glow discharge was applied, average excess powerof 1.6 watts was observed. if the error was 1 watts, the average super heat power 0.6 watts, cop=1.02, generate heat 8.6KJ.

2018年1月21日14.00- 17.00,在30瓦恒定功率辉光放电时出现超热,平均超热1.4瓦,如果减去误差1瓦,平均超热功率0.4瓦,cop=1.013,产生热量4.3KJ。

In 14:00 to 17:00 January 21, 2018, when 30 watts constant power of glow discharge was applied, average excess power of 1.4 watts was observed. if the error was 1 watts, the average super heat power 0.4 watts, cop=1.013, generate heat 4.3KJ.

上述四次超热合计产生热量65KJ。

The above four excess powers accruals produce heat 65 K

总结

summary

1、 容器温度异常升高现象,因为没有测到多余热量,分析为容器内部辉光放电位置漂移所致。

1. The abnormal increase of temperature of the container is caused by the measurement of not excess heat ,However, no excess heat was shown in the calorimetric measurement, which is caused by the shift of the position of the glow discharge in the container.

2、 观察到的超热量较小,与误差相比最大为2倍,未观测到大的超热现象。

2, the observed excess heat is small, and the maximum of the error is 2 times compared to the measured value, and the large anomalous heat is not observed.

3、 下一步实验拟改进量热计设计,减少误差,提高测量精度。

3. The next step is to improve the calorimeter design, reduce the error and improve the measurement accuracy.

参考文献

Reference

1、PREPRINT Mizuno, T. Method of controlling a chemically-induced nuclear reaction in metal nanoparticles. in ICCF18 Conference. 2013. University of Missouri.

2、Preprint J. Condensed Matter Nucl. Sci. 25 (2017),Observation of excess heat by activated metal and deuterium gas

致谢:本次实验得到中国科学院化学研究所张武寿先生和厦门大学黄崇恩先生的帮助。

Acknowledgements: This work was helped by Dr. Zhang Wushou at Institute of Chemistry , Chinese Academy of Sciences and Mr. Huang Chongen of Xiamen University,and Dr. Bob Higgins of MFMP.

附件,实验数据表

Appendix, experimental data sheet

总结

summary

1、 容器温度异常升高现象,因为没有测到多余热量,分析为容器内部辉光放电位置漂移所致。

1. The abnormal increase of temperature of the container is caused by the measurement of not excess heat ,However, no excess heat was shown in the calorimetric measurement, which is caused by the shift of the position of the glow discharge in the container.

2、 观察到的超热量较小,与误差相比最大为2倍,未观测到大的超热现象。

2, the observed excess heat is small, and the maximum of the error is 2 times compared to the measured value, and the large anomalous heat is not observed.

3、 下一步实验拟改进量热计设计,减少误差,提高测量精度。

3. The next step is to improve the calorimeter design, reduce the error and improve the measurement accuracy.

参考文献

Reference

1、PREPRINT Mizuno, T. Method of controlling a chemically-induced nuclear reaction in metal nanoparticles. in ICCF18 Conference. 2013. University of Missouri.

2、Preprint J. Condensed Matter Nucl. Sci. 25 (2017),Observation of excess heat by activated metal and deuterium gas

致谢:本次实验得到中国科学院化学研究所张武寿先生和厦门大学黄崇恩先生的帮助。

Acknowledgements: This work was helped by Dr. Zhang Wushou at Institute of Chemistry , Chinese Academy of Sciences and Mr. Huang Chongen of Xiamen University,and Dr. Bob Higgins of MFMP.

附件,实验数据表

Appendix, experimental data sheet

相关热词搜索:冷聚变,镍氢,辉光放电,LENR

分享到:

收藏

收藏

评论排行

- ·黑光能源公司 BlackLight Power, In...(4294967281)

- ·冷聚变技术可以结束当前的雾霾天气吗?(13)

- ·布里渊能源技术公司的CECR技术简介(9)

- ·Defkalion公司的5千瓦Hyperion冷聚变反应堆(8)

- ·截止2014年国内外冷聚变研究现状(8)

- ·美军宣称已成功将海水直接转化为燃料(8)

- ·关于近期对E-CAT真实性质疑的问题(8)

- ·中核研究院成功复制镍氢冷核聚变装置E-CAT(7)

- ·美预言家预测人类在未来18个月内实现冷...(6)

- ·黑光能源公司宣布改变能源领域游戏规则...(6)

- ·镍氢电能(E-CAT)研究中心落户天津(6)

- ·工业热力公司公告称罗西起诉没有任何价值(6)

- ·空中客车公司对冷核聚变研发感兴趣(5)

- ·1升水能让汽车跑5000公里(4)

- ·冷聚变开拓者:马丁. 弗莱希曼 和 斯...(4)

- ·世界上第一台冷聚变装置E-CAT的研发历程(4)

- ·冷聚变是伪科学吗?(4)

- ·冷聚变将引发环保和新能源技术新的革命(4)

- ·德国EGM公司的水基燃料技术(4)

- ·英国国防部最新报告:冷聚变技术将来会...(4)